Best for: Premium adhesion and durability onto EPDM and metal roofs.

Sikaflex 715 is one of the higher-end, semi-self-leveling sealant options and has always impressed me—it’s perfect for RVers seeking top-tier performance.

Whether you’re working on EPDM or metal surfaces, this sealant provides a reliable, watertight seal—even in those tricky, low-sloped, or awkward areas where other products might struggle.

With low VOC content and a crack-resistant formula, it’s built to endure the toughest challenges of RV travel.

During testing, I found the sealant's semi-self-leveling design allowed for precise, controlled application on uneven or slightly sloped areas, ensuring a clean and professional finish.

It offers primerless adhesion to properly prepared surfaces, so you don’t need anything extra, simplifying the whole process without compromising on strength.

Additionally, its long-lasting resistance to shrinking and cracking guarantees durability, even under extreme conditions. With an eco-friendly, low VOC formula, Sikaflex 715 combines top-tier performance with environmental responsibility.

In my opinion, this makes it the premium choice for RVers who value quality and sustainability.

Pro Tip: For optimal results, use a sealant primer on surfaces that might require enhanced adhesion.

Best for: Long-term flexibility around external vents, antennas, and roof penetrations.

When it comes to dependable RV roof sealants, Heng’s NuFlex 311 Silicone Caulk has earned its place as a trusted favorite among leading OEM manufacturers, including Winnebago.

I’ve relied on it for sealing roof penetrations of all types, and its exceptional pliability and durability never fail to impress. This caulk is built to last, resisting extreme temperatures and staying flexible for years, making it my top pick for anyone prioritizing long-term reliability under challenging conditions.

Engineered to withstand extreme temperatures ranging from -20°F to 122°F. I’ve used it in all kinds of weather, and it consistently maintains its integrity, no matter the conditions.

It’s also compatible with a range of materials, including fiberglass, making Heng’s NuFlex 311 one of the more versatile options in this list.

The self-leveling design is another highlight. It ensures smooth and seamless finishes on horizontal surfaces, while its long-lasting silicone formula provides unparalleled flexibility and durability.

Whether you’re tackling general maintenance or working on more demanding repairs, Heng’s NuFlex 311 delivers reliable performance for the long haul!

Pro Tip: Apply in thin layers when sealing large gaps to ensure strong, smooth adhesion and seal.

Best for: Repairs under immediate weather exposure.

If there’s one sealant I always recommend keeping in your repair kit, it’s Geocel Pro Flex RV Flexible Sealant.

This product is a true lifesaver when you need quick, weather-resistant repairs, especially in less-than-perfect conditions. What sets it apart is its ability to bond to damp or even slightly oily surfaces—something that’s come in handy more times than I can count.

The UV-stable and mildew-resistant formula ensures long-term durability, and the paintable finish allows for a seamless look that matches your aesthetic.

This sealant bonds effectively to fiberglass, aluminum, wood, and a variety of other surfaces making it one of the more versatile choices, along with Heng’s NuFlex 311.

Its resistance to UV damage and mildew ensures a clean and lasting seal, perfect for maintaining the appearance and functionality of your RV. This is the better choice if you frequent tougher climates.

One thing I really appreciate is the paintable finish. It blends seamlessly with your RV’s design, giving repairs a clean, professional look without compromising on functionality. Plus, the fact that it performs well immediately after application—even in harsh weather—makes it my go-to for emergencies and on-the-road fixes.

Whether you’re dealing with unexpected leaks or routine maintenance, Geocel Pro Flex is a reliable companion for any adventure. I recommend always keeping this one in your repair kit.

Pro Tip: Avoid using on EPDM roofs, or in applications involving potable water, to ensure compatibility and safety.

Best for: Those awkward vertical and uneven applications.

Alpha Systems 101 Low VOC Non-Sag Sealant is purpose-built for RV surfaces that demand precise application. Its non-sag formula ensures it stays exactly where you need it, even on challenging vertical or uneven surfaces like sidewalls and end rails.

This allows for a professional, clean finish without the risk of drips or messes, making it an excellent choice for detailed repairs.

What I really appreciate about this sealant is how well it holds up to the demands of RV travel. From sudden shocks to constant vibrations, it’s built to last, ensuring your repairs stay intact no matter where your journey takes you. It’s the kind of durability you can count on when the road gets rough.

In addition to its robust performance, this sealant features a low VOC formulation. Not only is it better for the environment, but it’s also safer to work with—a win-win in my book. Once cured, it can be painted to seamlessly integrate with your RV’s design, maintaining a polished appearance while offering reliable functionality.

For me, Alpha Systems 101 combines practicality, sustainability, and superior performance, making it the go-to solution for RVers tackling vertical or uneven maintenance challenges.

Pro Tip: Stick to vertical applications only, as this sealant is not formulated for horizontal surfaces and might not get the job done.

6. Lippert SuperFlex Non-Sag Roof Sealant

Best for: Pretty much every job—provides cost-effective versatility.

If you’re looking for a budget-friendly sealant that doesn’t compromise on quality, Lippert SuperFlex Non-Sag Roof Sealant is a fantastic option. I’ve recommended this product to plenty of RVers who need a dependable solution without breaking the bank, and it always delivers.

Capable of resisting temperatures as low as -40°F and withstanding damage from UV rays and ozone exposure, it ensures reliable performance in a wide range of weather conditions.

What I like most is its versatility. The sealant is compatible with multiple surfaces, including EPDM rubber, fiberglass, aluminum, and wood. So whatever materials your roof is made of, it should be able to provide a decent seal. Another key feature is its durability. It holds up well to long-term exposure to harsh environmental elements, making it a solid choice for RVers who spend a lot of time outdoors. And it’s pretty easy to apply, which is always a plus if you’re not a fan of overly complicated repairs.

Pro Tip: Always ensure proper ventilation during application, as the sealant contains materials that require you to wear an air mask or carry out work in a ventilated area.

Buying Tips for RV Roof Sealants

Still unsure which sealant is right for you? Here are my top tips and expert guidance for making sure you always get the right RV roof sealant for the job.

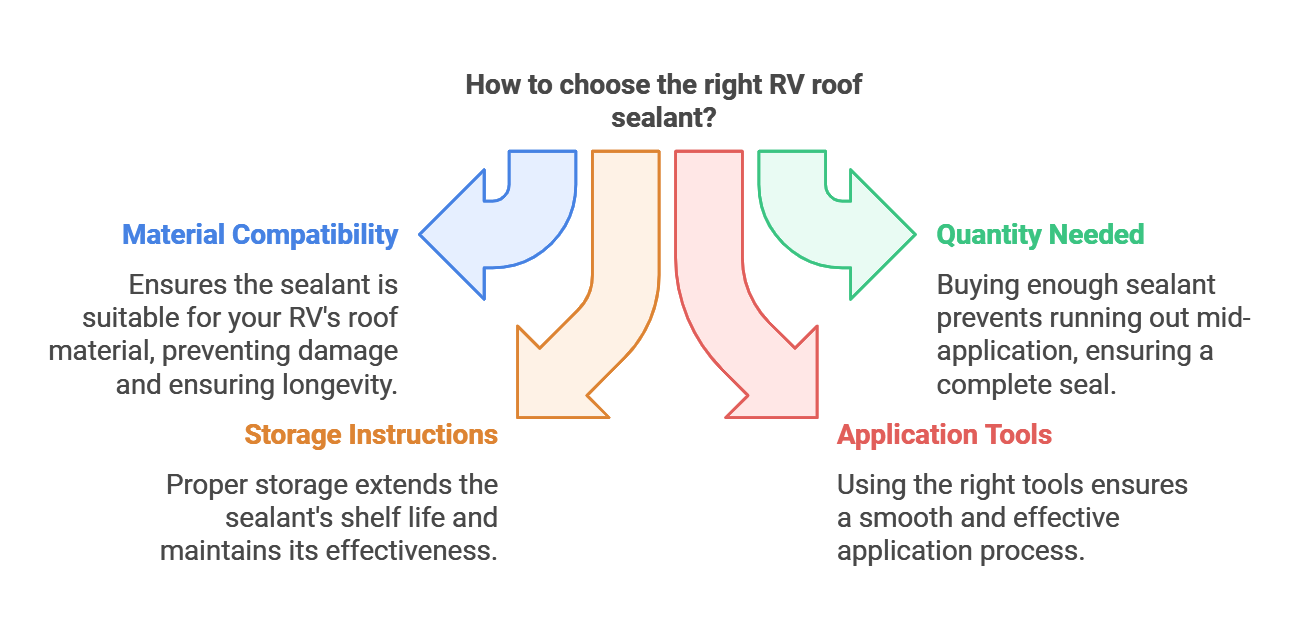

Consider Material Compatibility

Seems simple enough, but when buying a roof sealant, you need to make sure that the formula is compatible with your RV’s roof materials. Each material might require specific formulations for optimal performance.

Silicone-based sealants, like Heng’s NuFlex 311, work well with fiberglass; while the Dicor Self-Leveling Lap sealant is better for EPDM and TPO roofs.

Using incompatible sealant results in poor adhesion, leaks, damage—or just makes your roof look a bit shoddy—so always verify compatibility before purchasing (and adhesion!).

Make Sure You Buy Enough

Sealants come in various tube sizes, typically around 10 to 11 ounces, which can cover approximately 30 linear feet with a ¼-inch bead.

For smaller repairs, a single tube may suffice, but for larger projects, like sealing multiple skylights or seams, consider buying additional tubes to avoid running out mid-project.

Bigger projects are going to cost more, so make sure you’re planning ahead—this can save you both time and frustration, ensuring you have the right amount on hand for the job.

Check the Storage Instructions

Don’t just put it on the shelf and forget about it. To ensure your sealant remains effective, you need to store it correctly.

Most sealants should be kept in a cool, dry place and used within their recommended shelf life—often around 12 months. Sealants like Alpha Systems 101 and Sikaflex 715 are sensitive to environmental conditions, so always check the expiration date and make sure you can provide adequate storage conditions for whichever product you choose.

Invest In the Right Application Tools

Using the right tools can make a significant difference in the quality of your repair. A high-quality caulking gun is essential for applying products like Lippert SuperFlex or Dicor Self-Leveling Sealant smoothly and evenly.

For vertical applications, a non-sag sealant like Alpha Systems 101 will require precision, so opt for a gun that allows controlled application to avoid mess.

If you don’t want to buy any extra tools, look for a sealant that's a bit easier to apply

Download your FREE Roof Maintenance Guide

Protect your RV roof and enjoy stress-free travels. Download our Free RV Roof Maintenance Guide and learn the essential tips to prevent leaks, extend your roof's lifespan, and stay road-ready.

About the Author

I’m Bill Rowell, the founder of RVupgrades.com. In 2002, I launched the business to help fellow RV enthusiasts find unique and hard-to-find products. Over the years, it’s grown to offer more than 15,000 items, with a warehouse in Eastlake, Ohio. Having owned and repaired nearly every type of RV, I bring over two decades of hands-on experience to the table. For me, this isn’t just a business—it’s a passion and a way of life that I love sharing with the RV community.

Follow me on LinkedIn